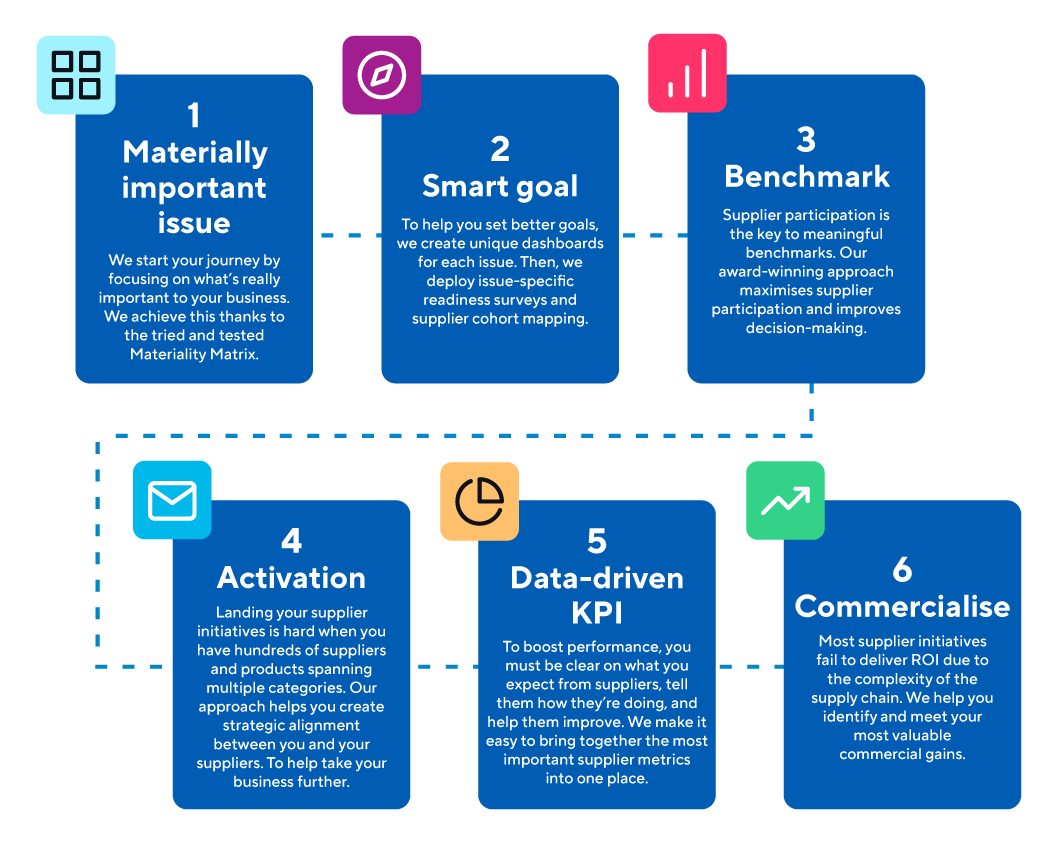

Applying the Six-Step Process to country of origin food labelling

Step one: Materially important issue

Due to the introduction of a new country of origin food labelling system into law, collecting this supply chain data became a materially important issue for Woolworths. This meant that the first step of the process had already been complete. Around half of our customers begin working with us at step two, having identified the important issues to their business and stakeholders internally.

Step two: Smart Goal

The primary goal of the project was to collect the country of origin data from suppliers required by the new legislation. But it would also enable Woolworths to identify any out of date product or supplier data, add new products to the system, and improve their overall data integrity.

Step three: Benchmark

The purpose of establishing a benchmark was to understand how Woolworths were currently performing against their SMART goal - in short, how much country of origin data did they already have.

But before the launch of the country of origin survey, Supply Pilot's Campaign Team ran a supplier contact accuracy campaign. This campaign ensures that, when we request suppliers to provide country of origin information for the products they supply, it is sent to the right person within the supplier's organisation. As part of this phase of the project, the "why" behind the project was communicated to suppliers so they understand the significance, scope, and steps that needed to be taken for the new piece of legislation. It also provided an opportunity for Woolworths to emphasis the importance and commercial opportunity of product provenance as part of their category strategy.

Typically retailer and brand supplier data is only 18% accurate. This low level of contact accuracy means that supply chain data collection exercises can be delayed by months whilst emails are sent to:

- inactive inboxes

- incorrect contacts

- commercial contacts who don't have the appropriate level of knowledge or the right information to hand

Step four: Activation

The vast number of products within the Woolworths portfolio and the consequences of not adhering to the legislation required a quick solution. Manufacturing and artwork lead times meant that the retailer’s deadline needed to be considerably earlier than the government’s deadline.

This meant that having a collaborative approach with suppliers was more important than ever. Pre-populating known data for suppliers completing the product information survey (rather than using the historical ‘blank spreadsheet’ approach) was vital to ensure the efficiency of the project by reducing the burden on suppliers.

Supply Pilot’s expertise in supplier engagement led to a rapid response rate with 70% of all branded and own brand product information submitted within two months of the project being launched. Suppliers were able to use the Supply Pilot Platform to inform Woolworths of their new country of origin statements for both own brand and branded products.

Step five: Data-driven KPI

For most retailers running this type of campaign, problems typically surface further down the line when the data is in and the reporting begins. To avoid this, the Supply Pilot Platform provides supplier dashboards that show which information within a product specification or product lifecycle management (PLM) system has been provided by suppliers. This enables data to be loaded into systems in increments which has been instrumental in ensuring artwork lead times can be met.

This step of the process also included keeping the data up-to-date after the regulation deadline via data quality education campaigns and data completeness dashboards.

Step six: Commercialisation

The supplier engagement campaign was run alongside the launch of Woolworths supplier portal.

As well as collecting the detailed information required, the exercise identified any out of date product data for inactive products, which could then be corrected for data integrity purposes, and allowed many new products to be added to the system, resulting in a highly accurate report on the volume of products needing action.

Woolworths was then able to risk assess the impact of the labelling legislation changes as a business and take the necessary action to ensure compliance by the July 2018 deadline.