From a sustainability standpoint, brand and retailer marketing materials used at the point of purchase (POP) or point of sale (POS) present a problem, similar to that of single-use packaging. Most often, they are designed for one use and to be thrown away afterwards due to their high customisation to a particular product range or campaign.

Unfortunately, the environmental consequence of these brand assets is too often overlooked, with many a sustainability strategy being mostly aligned with direct procurement activities. This also translates to less well-resourced indirect procurement teams. However, indirect procurement is a major contributor to a business’ Scope 3 (supply chain) emissions and should not be left unmeasured.

Prioritise high impact initiatives

There are many solutions and strategies around more responsible and sustainable printed materials. For example, the use of vegetable-based inks, designing out waste, or optimising design to reduce the need for petrochemical-derived glues. However, a lack of internal resource will always call for a focus on high impact over the short term. And within the context of POP and POS, material recyclability and plastic reduction come top of the list.

A single view to track and record tangible progress

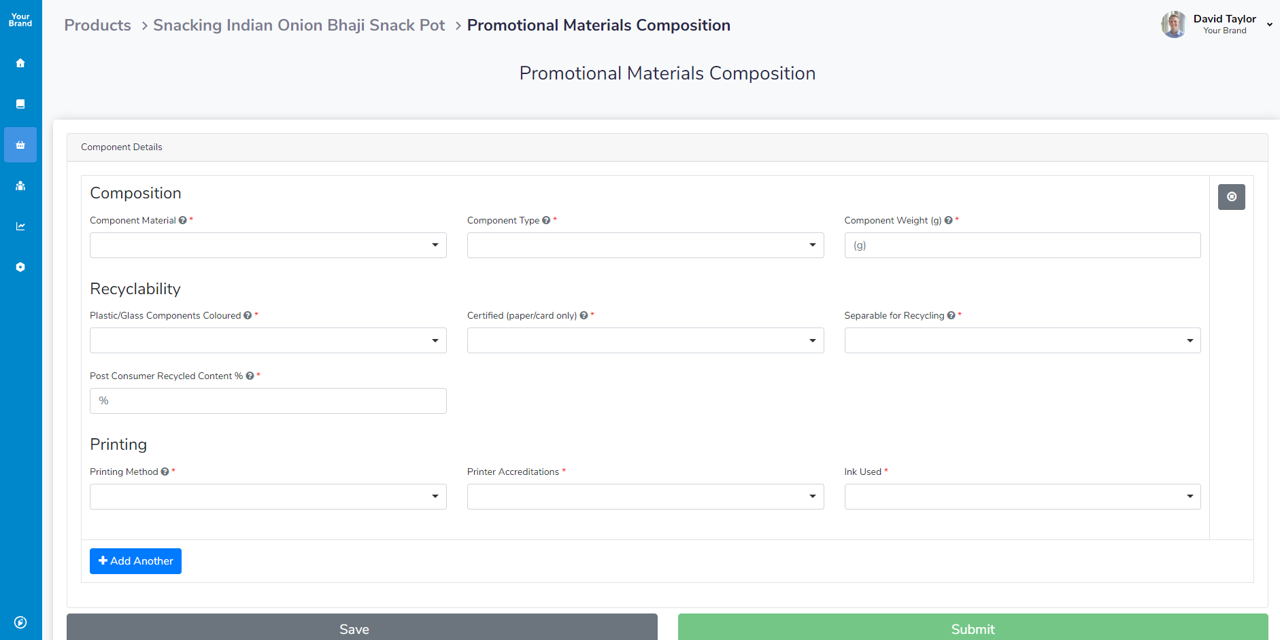

As a baseline for either initiative, brands need a comprehensive overview (or benchmark) of the composition of their POS and POP materials. This enables brands to visualise (and track) what materials are being used (be it plastic or an alternative) and whether or not those individual materials affect the recyclability of the final product.

However, for many procurement teams, attempting to create such an overview can be a very time-intensive and manual operation, usually relying on spreadsheets and email communication. It becomes especially difficult during a recyclability initiative when teams want to track the change in materials (e.g. from non-recyclable to recyclable) from dozens or hundreds of suppliers. A single-view of the data is crucial to being able to track progress towards specific goals – otherwise data can be out of date, inconsistent, and incomplete if collected manually from so many suppliers. This can potentially damage the integrity of the data and any subsequent reports.

Understanding supplier readiness for change

Any visualisation tool is a bit useless if it does not have the data to feed into it, however elegant a solution it is. This is why engaging suppliers via a readiness survey specifically about the material composition of your POS/POP materials is a crucial step. This enables you to first understand the maturity of suppliers when it comes to not just the composition of materials, but also their recyclability. This can assist in determining out a specific, measurable, attainable, realistic, and timebound (SMART) goal – if this is something you are yet to do.

The readiness survey will also enable you to communicate with suppliers throughout the entire initiative (and any subsequent projects) at a level which is appropriate for their knowledge around the topic. This is essential when working with several hundred suppliers at once to maximise engagement and responses. It will also significantly improve the accuracy and reliability of data collected at the next step when you establish a benchmark of current recyclable vs non-recyclable materials in POS/POP materials.

The value of supplier readiness becomes evident later on in the initiative too, as it enables you to tap into the expertise from suppliers at a higher level of topical maturity whilst simultaneously boosting the knowledge of suppliers at lower levels of maturity. A centralised knowledge base and targeted education campaigns can help to elevate knowledge of material recyclability throughout the supply chain, complete any missing data, and close the gap between your current benchmark and your ultimate goal.

Make recyclability a reality

Brands need to also ensure that their POS and POP materials promote recyclability at end of life. This means working with suppliers to make sure that any instructions relating to the disassembly and recyclability of POS and POP materials are intact, available, and inseparable from the unit, right until end of life. This could be something as simple as a printed QR code on the unit. However, this is only possible at the final step of a successful supplier collaboration project around the recyclability of composition materials.

Heavy lies the crown of responsibility

With the majority of the world’s plastic waste ending up in landfills or incinerators instead of being recycling, a brand sustainability strategy (however large or small) which focuses solely on recyclability no longer lets business off the hook – it essentially pawns off responsibility onto an infrastructure that cannot yet keep up. This means that supply chain initiatives focused on the reduction of plastics must also remain a priority for brand and retailer’s POS and POP assets.

This could easily be built on the back of the data collected from a robust material composition or plastic recyclability initiative, leveraging the expertise already within the supply base to open doors to innovation around material composition and plastic alternatives.